OUR PRODUCT GROUPS

Please contact us for all your requests...

+90(545) 278 45 01

+90(545) 278 45 01

PLAN TEKNIK

10th YEAR

| Model | Pipe size mm. |

Pipe size inch |

Force Kn. |

Motor | Control System | Vacuum | Camera | Lighting | Trimming | Package sizes | Kg. | ||||

| H | B | L | |||||||||||||

| PITR 12-14 | Ø 323,90 | Ø 355,60 | 12'' | 14'' | - | 1 | Wifi | No | Yes | No | No | ||||

| PITR 16-18 | Ø 406,40 | Ø 457,20 | 16'' | 18'' | - | 1 | Wifi | No | Yes | No | No | ||||

| PITR 20-22 | Ø 508,00 | Ø 558,80 | 20'' | 22'' | - | 1 | Wifi | No | Yes | No | No | ||||

| PITR 24-26 | Ø 609,60 | Ø 660,40 | 24'' | 26'' | - | 1 | Wifi | No | Yes | No | No | ||||

| PITR 28-28 | Ø 660,40 | Ø 711,60 | 26'' | 28'' | 3,53 | 1 | Wifi | No | Yes | One | Yes | ||||

| PITR 28-30 | Ø 711,60 | Ø 762,00 | 28'' | 30'' | 3,53 | 1 | Wifi | No | Yes | One | Yes | ||||

| PITR 30-32 | Ø 762,00 | Ø 812,80 | 30'' | 32'' | 3,53 | 1 | Wifi | No | Yes | One | Yes | ||||

| PITR 32-34 | Ø 812,80 | Ø 863,60 | 32'' | 34'' | 3,53 | 1 | Wifi | No | Yes | One | Yes | ||||

| PITR 32-36 | Ø 812,80 | Ø 914,40 | 32'' | 36'' | 3,53 | 1 | Wifi | No | Yes | One | Yes | ||||

| PITR 34-36 | Ø 863,60 | Ø 914,40 | 34'' | 36'' | 3,53 | 1 | Wifi | Yes | Yes | One | Yes | ||||

| PITR 36-38 | Ø 914,40 | Ø 965,00 | 36'' | 38'' | 3,53 | 1 | Wifi | Yes | Yes | One | Yes | ||||

| PITR 36-40 | Ø 914,40 | Ø 1016,00 | 36'' | 40'' | 3,53 | 1 | Wifi | Yes | Yes | One | Yes | ||||

| PITR 38-40 | Ø 965,00 | Ø 1016,00 | 38'' | 40'' | 3,53 | 1 | Wifi | Yes | Yes | One | Yes | ||||

| PITR 40-42 | Ø 1016,00 | Ø1067,00 | 40'' | 42'' | 3,53 | 2 | Wifi | Yes | Yes | two | Yes | ||||

| PITR 40-44 | Ø 1016,00 | Ø 1118,00 | 40'' | 44'' | 3,53 | 2 | Wifi | Yes | Yes | two | Yes | ||||

| PITR 42-44 | Ø1067,00 | Ø 1118,00 | 42'' | 44'' | 3,53 | 2 | Wifi | Yes | Yes | two | |||||

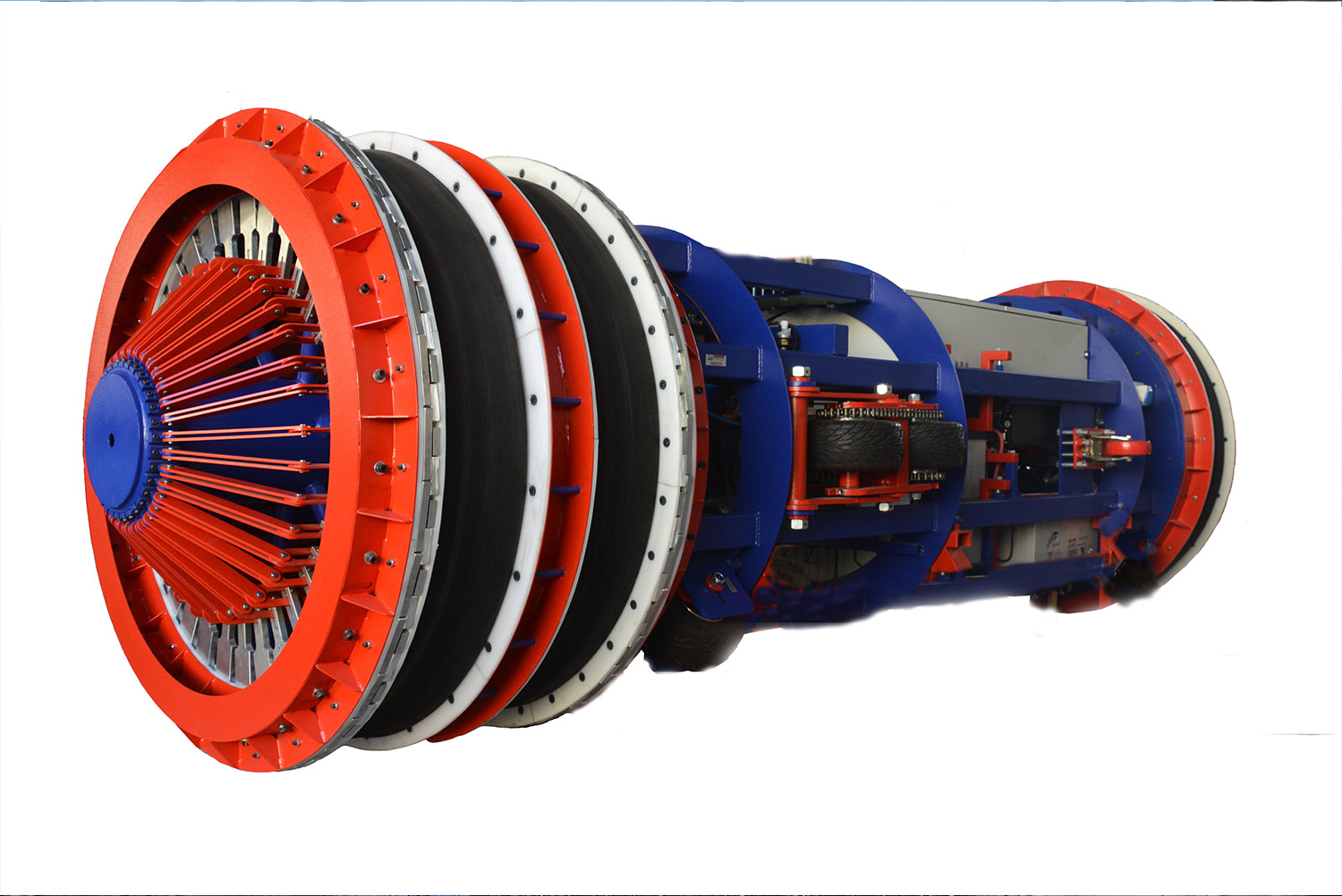

Pneumatic test system for testing the connections of pipes used in pipeline installations is a test method with air without the use of liquids and consumables.

Pipe joint test system is placed inside the pipe section to be tested. The test system creates a closed-loop pressure medium within the pipe and monitors the pressure of the medium for leakage and / or pressure loss in the pipe section to be tested.

Method is characterized in that the device comprises a first wall portion including a first sealing means and a second wall portion comprising a second sealing means.

If the pipe section to be tested, in particular the connection point, is between the first wall portion and the second wall portion; the sealing means of the first wall portion is brought more tightly to the inner surface of the pipe. The sealing means of the second wall portion is brought more tightly to the inner surface of the pipe. The pressure medium is brought into the chamber cavity delimited by the first wall portion, the second wall portion, and the inner wall surface. The pressure in the pipe section is measured. It detects if there is a possible leakage of the pressure change or pipe section.

Testable pipe types: GRP – Corrugated – Corrugated Triplex – PE – PVC – Steel – Ductile HDPE

For HDPE Pipe Joints: It can perform cutting and inserting the inner lips formed at the joint site.

Auto Control: Determination of ovality in pipe

Imaging: In-Tube Ultra HD Camera

Lighting: Led

Distance Measurement: Determination of pipeline length

Marker: Laser

Temperature Detection: 3m optical heat measurement

In-pipe surface quality detection: In-pipe 360 ° Rotation Ultra HD Camera

Temperature Detection: In-pipe ambient temperature detection (lip stripping for pipes for HDPE)

Pressure Test: Creation of working pressure and working test pressure by forming air cell under 175 psi pressure (12 bar)

Pressure Equipment: Mono block compressor 50 lt.gf

Pipe Joint Test: Oring and Gasket Tests

Limit Speed: 1m – 24 m / min.

System Control (Optional): Wi-fi, bluetooth and Cable

System Energy: DC 24 Volt

Reporting: Pressure test, Length, Ovality, EXCEL formation and Imaging Record HD Mp4 format.

Warranty: 2 years.