OUR PRODUCT GROUPS

Please contact us for all your requests...

+90(545) 278 45 01

+90(545) 278 45 01

PLAN TEKNIK

10th YEAR

| Model | Pipe size mm. |

Pipe size inch | Force | Force application | Force type | Number of parts |

Package sizes | Kg. | ||

| H | B | L | ||||||||

| OBKK-273 | 273,00 | 10 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-323 | 323,90 | 12 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-355 | 355,60 | 14 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-406 | 406,40 | 16 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-457 | 457,20 | 18 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-508 | 508,00 | 20 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-558 | 558,80 | 22 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-609 | 609,60 | 24 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-660 | 660,40 | 26 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-711 | 711,60 | 28 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-762 | 762,00 | 30 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-812 | 812,80 | 32 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-863 | 863,60 | 34 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-914 | 914,40 | 36 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-965 | 965,00 | 38 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-1016 | 1.016,00 | 40 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-1067 | 1.067,00 | 42 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-1118 | 1.118,00 | 44 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-1168 | 1.168,00 | 46 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-1219 | 1.219,00 | 48 | Socket wrench | screw | Circle | 6 | ||||

| OBKK-1270 | 1.270,00 | 50 | Socket wrench | screw | Circle | 6 | ||||

Calculation of Pipe Ovality Defect Value?

First, the diameters of the pipes will be measured. Depending on the manufacturer's discretion, a circumference band or diameter gage can be used.

If an agreement is reached, other measurement methods can also be used.

You may get radiographic errors in the weld test due to ovolites formed by deformation and pressure on the pipes.

The small, seemingly insignificant details you've overlooked can lead to significant losses.

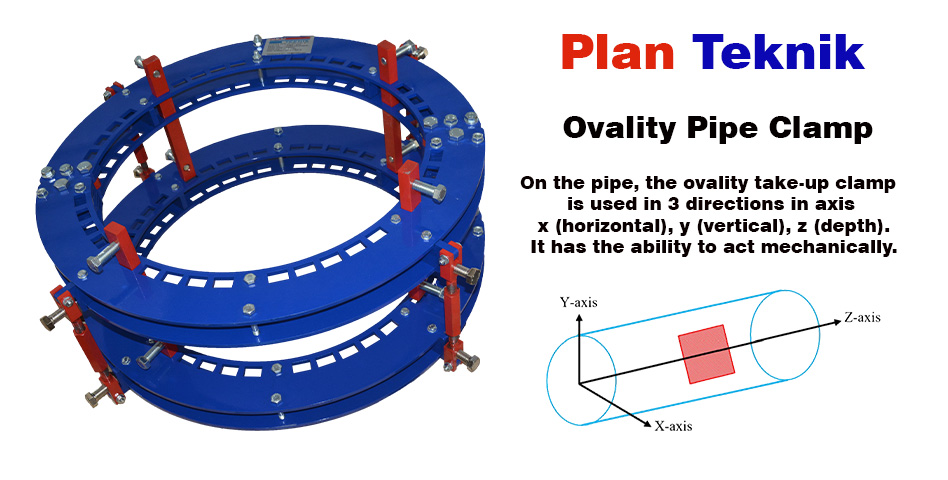

When there are slight millimeter differences in pipe diameters or ovality defects in pipes of the same diameter, the ovality of the pipes must be corrected using appropriate clamp fittings.

Clamps can significantly reduce these types of error rates.

In pipelines; pipe alignment clamps should be used in order to make pipe connections in the best way and in the shortest time.

Suitable for use in all areas; construction site, factory, workshop etc. And they are ergonomic, robust and lightweight tools.

Multi-point contact with your pipe to hold the cage from the position.Is used for the correct alignment and assembly of additive parts; pipe, elbow, welding neck flange, Te, reduction, cap, intermediate fittings and branch elements.

Ovality Clamp improves the performance of the water flow rate when used during installation of pipes. Reduces labor cost during assembly. Ergonomically designed for easy use.

Prevents pipe, fittings and branch elements from being damaged during assembly. Reduces labor cost during assembly.

Prevents pipe, fittings and branch elements from being damaged during assembly. Reduces installation time by 80%. Does not take up much space in the installation site.

Due to their mechanical structure, these clamps can be left on the pipe for a long time during installation.

For stainless and coated pipes, it is recommended to use special contact pressure series.