OUR PRODUCT GROUPS

Please contact us for all your requests...

+90(545) 278 45 01

+90(545) 278 45 01

PLAN TEKNIK

10th YEAR

| Model | Pipe size mm. |

Pipe size inch | Force application | Force type | Number of parts | Package sizes | Kg. | ||

| H | B | L | |||||||

| VBKK-273 | 273,00 | 10 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-323 | 323,90 | 12 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-355 | 355,60 | 14 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-406 | 406,40 | 16 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-457 | 457,20 | 18 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-508 | 508,00 | 20 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-558 | 558,80 | 22 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-609 | 609,60 | 24 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-660 | 660,40 | 26 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-711 | 711,60 | 28 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-762 | 762,00 | 30 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-812 | 812,80 | 32 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-863 | 863,60 | 34 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-914 | 914,40 | 36 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-965 | 965,00 | 38 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-1016 | 1.016,00 | 40 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-1067 | 1.067,00 | 42 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-1118 | 1.118,00 | 44 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-1168 | 1.168,00 | 46 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-1219 | 1.219,00 | 48 | Wrench with Ratchet | screw | 4 | ||||

| VBKK-1270 | 1.270,00 | 50 | Wrench with Ratchet | screw | 4 | ||||

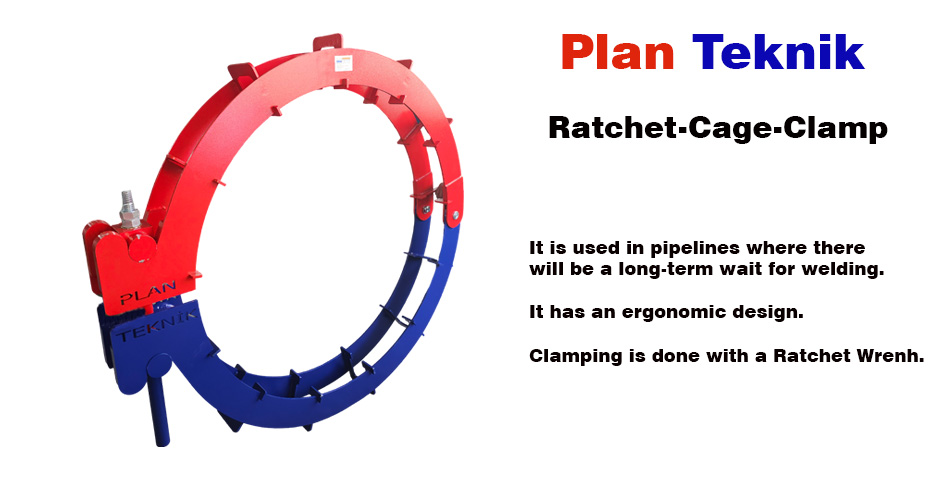

In pipelines; pipe alignment clamps should be used in order to make pipe connections in the best way and in the shortest time.

Suitable for use in all areas; construction site, factory, workshop etc. And they are ergonomic, robust and lightweight tools.

Multi-point contact with your pipe to hold the cage from the position.Is used for the correct alignment and assembly of additive parts; pipe, elbow, welding neck flange, Te, reduction, cap, intermediate fittings and branch elements.

External Ratchet Cage Clamps, increase the performance of the water flow rate when used during installation of the pipes.

Reduces labor cost during assembly.

Prevents pipe, fittings and branch elements from being damaged during assembly.

Ergonomically designed for easy and quick use.

The easy use of the apparatus makes it suitable for all areas and makes it easy to use.

Reduces installation time by 90%. Does not take up much space in the installation site. Reduces labor cost during assembly.

Due to their mechanical structure, these clamps can be left on the pipe for a long time during installation.

For stainless and coated pipes, it is recommended to use special contact pressure series.

Technical Specifications

It applies force to the outer surface of the pipe as a cage with multiple points in a circular circumference according to the pipe diameter and wall thickness.

Since the pressure force is manual screw + nut, it can be adjusted easily. Provides precise alignment with multi-point pipe-to-pipe contact.

Screw + nut used in force application process is tightened with ratchet wrench.

General adjustment consists of 1 point. After alignment, you can release the clamping screw by turning it with the ratchet wrench.

Security; during installation clamp has safety lock at1-point against falling.

The upper and lower arms safety chain prevents the clamp from falling apart when the middle jaw clamping block is not retained.

Resistant to welding effect temperature during installation.

Can be used in coated pipes. It is recommended to use in pipes with pipe wall thicknesses between 8mm and 20mm.

The block parts are easy to separate when needed and the block parts are replaceable.

This versatile handy tool consists of a main body and an intermediate wall steel plate.

Our products are manufactured using precision Laser Technology and CNC technology.

These products are guaranteed for 2 years.