OUR PRODUCT GROUPS

Please contact us for all your requests...

+90(545) 278 45 01

+90(545) 278 45 01

PLAN TEKNIK

10th YEAR

| Model | Pipe size Ø mm. |

Pipe size inch |

Cutting speed mm/min. | Motor | Control system | Pipe Contact | Package sizes | Net Kg. |

||||

| H | B | L | ||||||||||

| ZBKM 508 | 273,00 | 508,00 | 10 | 20 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 762 | 273,00 | 762,00 | 10 | 30 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 1016 | 273,00 | 1.016,00 | 10 | 40 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 1270 | 273,00 | 1.270,00 | 10 | 50 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 1524 | 273,00 | 1.524,00 | 10 | 60 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 1829 | 273,00 | 1.829,00 | 10 | 72 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 2032 | 273,00 | 2.032,00 | 10 | 80 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 2337 | 273,00 | 2.337,00 | 10 | 92 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 2540 | 273,00 | 2.540,00 | 10 | 100 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 2845 | 273,00 | 2.845,00 | 10 | 112 | 50-1150 | 1 | Cable | Steel | ||||

| ZBKM 3048 | 273,00 | 3.048,00 | 10 | 120 | 50-1150 | 1 | Cable | Steel | ||||

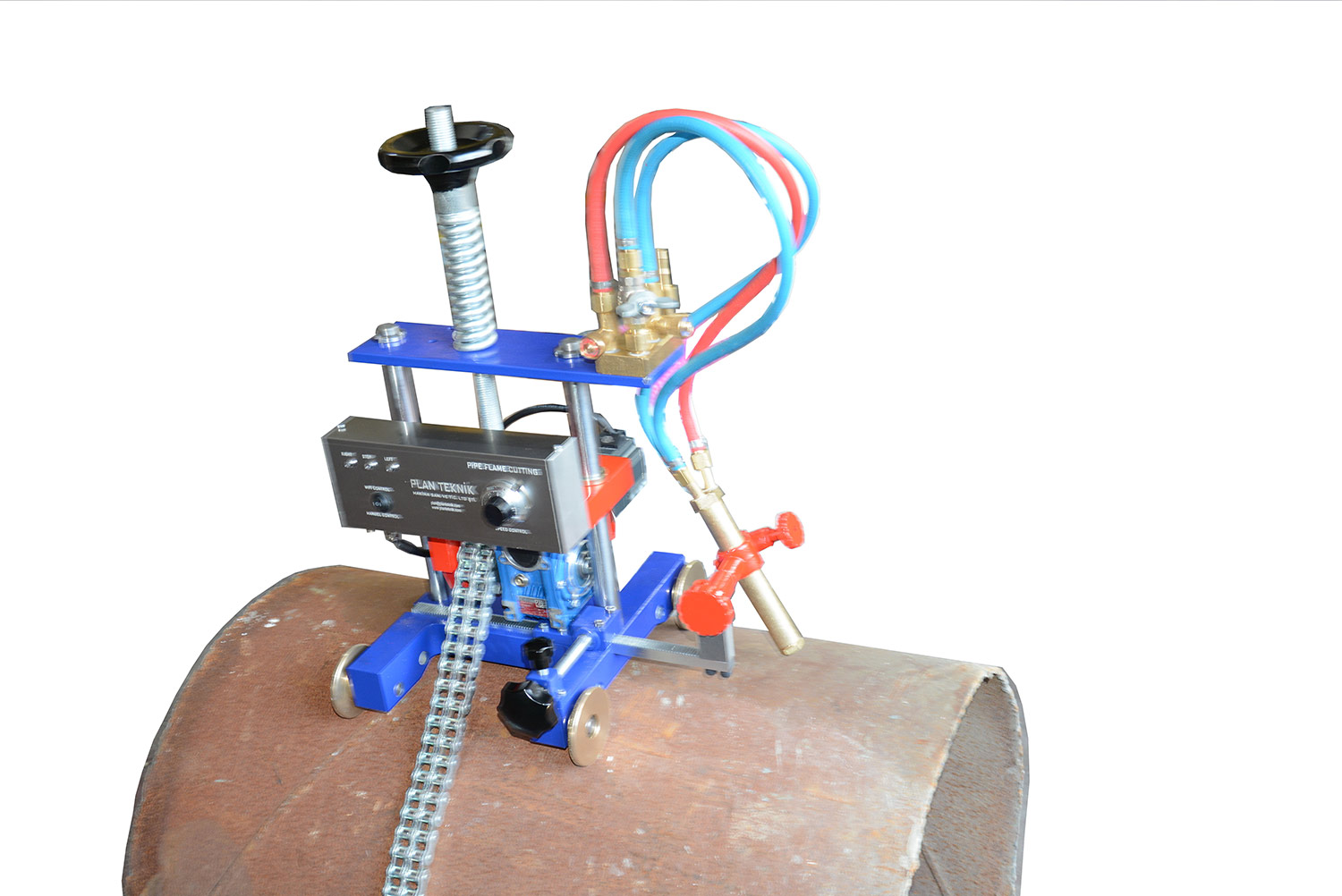

The Flame Cutting Machine's main body is made of aluminum alloy and features a stylish and portable design.

The system can be used with 24V DC and Wi-Fi control, or via cable.

The columns are chrome-plated.

The feed wheels on the pipe are made of yellow material.

The pipe rotation system is achieved by chain wrapping.

It can also be equipped with chain wrapping and a belt system upon request.

It operates via a reduction gear unit coupled to a dedicated geared motor. It has precise speed control.

The cutter is propane-injected.

It provides precise and smooth cutting capabilities for beveling pipe edges, beveling welds at desired angles, and cutting depths up to 50 mm.

It can be mounted on the pipe in horizontal, vertical, and angled positions. Its practical use makes it ideal for pipe cutting.

15. 2 years warranty